Clutch Designs and How They Work

Clutch Design and Function is definitely worth learning more about. While there are different styles, sizes, and plate numbers used on different bikes, their job and purpose is the same.

I do have a problem, I’ll admit that. Whenever someone ask me something that I feel he/she really needs to know, then my problem is giving a simple “Yes or No” answer. For some reason, I feel it a duty, an almost obligation to give them the answer and the reasoning behind that answer. Recently, a 16 year old cousin of mine was in my shop watching me assemble his Yamaha TTR’s cylinder head and valve train after surfacing the valves. The assembly is part of a full rebuild of his top end (piston, rings, bore) that he wanted my help with. His question to me was – “will popping my clutch hurt my bike?” Well, I knew the answer and had 10 reasons for why, but it would be wrong to just say “Yes”. We’ve all done it and on the smaller 4-strokes like his, it is almost a requirement for any fun to be had lofting the front wheel. I have assembled hundreds of clutches so I said Yes. “But, it’s OK” I added. I then related it to a tire and added that it’s one of those things you can and will abuse, but you will see loss of smoothness, performance, and will eventually have to replace it.

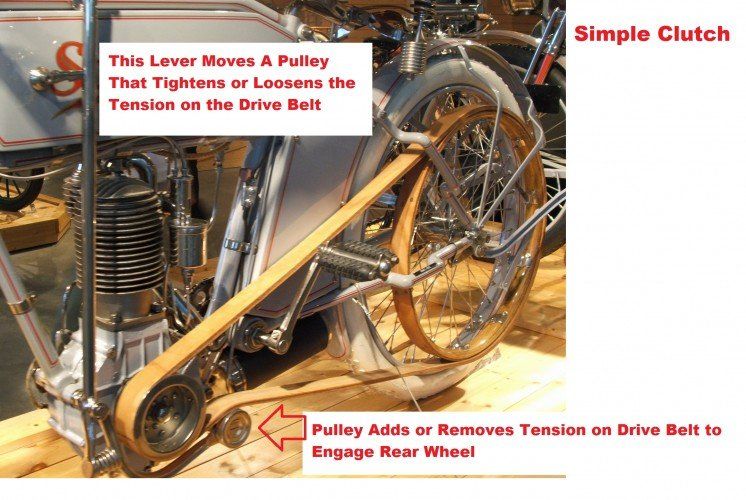

Knowing how a motorcycle clutch works and what happens at the “pop” will help you recognize operational problems if they develop. This discussion and the photos I’ve attached will hopefully give you what to look for when you do inspect the clutch. While almost every “wet clutch” is the same with regard to stacking alternate steel plates and friction disc, I’ve been amazed at the differences in how those plates/disc are opened. This subject of opening/disengaging is one that has two methods as different as Fred Flintstone and George Jetson. I’ll save that for another article within this same category, so you’ll come back. In it’s simplest form, a clutch transfers engine power to the drive wheel. I don’t know of anything more simple than the old Belt and Pulley System wherein a lever is used to Add or Remove tension to the Belt. A tight belt drives the rear wheel, a loose belt allows it to slip.

• The Wet Clutch used in our motorcycles is not a lot different in theory – the Stack is Tight, Loose, or something in-between and we’re able to stop and go in direct relationship to the friction between the drive and driven plates.

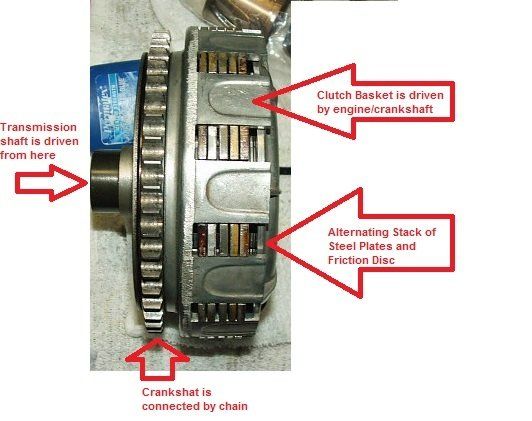

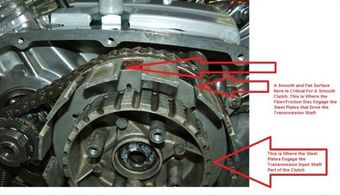

• The Basket is the large outer part of the clutch. This basket is usually made of aluminum and is driven by the engine/crankshaft, so it will turn whenever the engine is running. The Friction Disc have large tabs on their outer circumference that engage with the basket, so they too turn when the engine is running.

• The inner hub is usually aluminum and is splined to the input shaft of the transmission. The Steel Plates have rounded teeth on the inside diameter that engage with the inner hub.

• The Friction Disc and Steel Plates are sandwiched in alternating layers (stack) Fiber/Steel/Fiber/Steel and so on. It is these alternating Plates and Disc that allow variable transfer of power to the rear wheel through the driveline.

• An array of Strong Springs push the sandwiched stack together and would keep the Steel Plates and Fiber Disc from slipping at all. Pushed together/engaged is how the stack lives inside the clutch.

• A Throwout, lifter, or pusher is used to “push apart” the outer basket and inner hub so the sandwiched stack is disengaged – the Steel Plates and Friction Disc can now turn separately because the throwout has allowed a small space between each plate.

• When disengaged (pushed apart), the power (Friction Disc) from the engine is not acting upon the transmission (Steel Plates) so we’re able to sit at a stop light at rest and shift to different gears because the clutch is not transferring power/energy.

• This pushing apart/disengagement is of course variable by use of the clutch lever. If we slowly close the separation by releasing the lever, then a smooth clutch and action would have us easing away from full stop to go as we allow the “stack” to tighten.

Ok, so here is where the downside to Popping the Clutch comes. Those large Tabs on the outside circumference of the Fiber Disc are a very hard, tough metal. When they are “hammered” into the fingers of the outer basket by the sudden engagement when the clutch is “popped”, the smooth edges get chewed up and will eventually become rough. Over time and repeated abuse, they can/will wear the slots to the point that the Tabs won’t slide when the clutch lever is pulled. Even though the Throwout, (lifter, pusher) opens the clutch for spacing, the Friction Disc won’t move as far or as quickly resulting in rough take-offs, hanging/sticking clutch, difficult neutrals, and harder shifting. Those slots in the outer basket need to be smooth and slick in order for the “Sandwiched Stack” to open/separate quickly and smoothly. If you’ve got a bike with these symptoms, inspect your clutch and those finger slots that your Friction Disc slide in – there in your cause is likely to be.

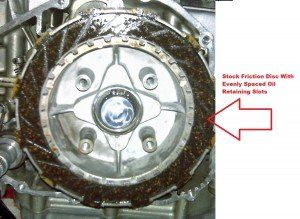

I’ve been bitten by the “Race Clutch” bug twice. Never again. I never have nor am I likely to ever need a Race Clutch. First, the real problem for me was that anytime the bike sat for more than 24 hours, the Steel Plates and Race Fiber Disc would stick together. The Race Fiber Disc had a lot more surface area that stock plates. The example shown has only 4 oil slots. Remember the discussion a minute ago about the small space opening up between plates so the plates could slip? Well, the Race Fiber Disc stick and hold the metal plates so well that the combination “sticks” even when they are asked to open and slip. I would have to rock the bike back and forth in gear and many times, have to push it and start while rolling. It could take several minutes to get the Disc and Plates warmed and separated. I did not need that much “stick” and I never liked the way it hammered on the transmission when going in gear. I’ve attached images of that Race Fiber and the Stock Fiber – you can see the stock ones have evenly spaced oil slots designed to help the sandwiched stack open.

Performance Builds? I’ll use performance/HD springs that hold the Stack together with much higher tension, but always use Stock Fibers and I love the results. I’ve done that on all of my stock bikes and the built Honda 836 and my Kawasaki H2 Drag with no problems all the while enjoying factory slick shifting.